Menu

Met-Chem has an onsite lab where we have the ability to run wastewater treatment and filtration testing. These tests are will help determine which wastewater treatment equipment is best suited for your specific application.

These tests can also help us troubleshoot any filtration or wastewater treatment issues that you may have which includes poor sludge development and cloth blinding to name a few.

Please contact Met-Chem for wastewater treatment testing, or if you are having any trouble with your current wastewater treatment equipment.

Met-Chem’s Filter Press Feasibility Test is our most popular and common test conducted in our lab. This test is performed to ensure that a filter press is able to filter solids properly with your specific application. The test will allow us to determine cloth sizing and if any filter aid will be required for your slurry. With less than a gallon of your typical wastewater, we can see if a filter press will provide the desired result. We will then send you the filtrate (liquid) as well as the solids that we are able to separate from your waste stream. The filter press test will also provide information to estimate the percentage of solids in order to properly size a filter press unit.

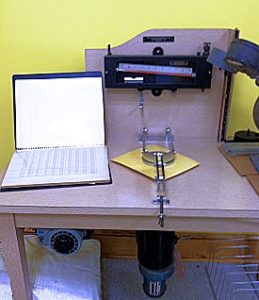

In the diagram below, Met-Chem was able to take a sample slurry and filter the liquid from the solids.

Another standard test is a sludge dryer test. With this test, we take the filter cake (solids that have been separated from your waste stream from a filter press) and we heat them in our lab in a sludge dryer simulation oven. This tells us if a sludge dryer will be beneficial and also helps in assessing the total drying time and solids reduction that you should expect.

Met-Chem routinely conducts flow rate testing via our Frazier tester. The Frazier test helps us to determine the air permeability of a given fabric. It measures air flow and rates fabric by CFM rating. This is the widely accepted industry standard to measure permeability. It is actually more accurate than micron rating as air has no shape or size.

Our other testing is more involved. These analyses are conducted for full waste treatment systems or we can focus solely on specific aspects of your system. This type of testing provides information on the amount and what type of chemistry that will be required of your system from pH adjust to polymer additions in order to keep your wastewater treatment system operating at the optimal level.

Please note that there is a charge for some of our testing. However, the cost of the test is deductible from a future purchase.

Met-Chem’s Evaporator Feasibility Test will determine if your wastewater is able to be treated with evaporation. The evaporation test will allow us to give operating recommendations to treat your wastewater, and it will allow us to optimize the performance of your evaporator. This testing will also reveal if any complications could arise during evaporation, such as foaming and volatile substances to name a few.

Our waste stream analysis is unique just as every waste stream is unique. Our testing provides an accurate demonstration of how each waste stream will function in an evaporator. Ultimately we will be able to determine the expected reduction wastewater volume which is typically 90-99%.

For applications that need larger test samples, or if testing must be conducted on your jobsite, Met-Chem have testing units that can be temporarily installed. This will allow us to see if the desired results can be achieved.

For applications where the lab testing must be larger than what our traditional test can offer or that must be run at a customer’s job site, Met-Chem is pleased to offer our ½ cubic foot Rental Filter Press. The unit is a manual hydraulic filter press with 3 gasketed filter press plates. Each plate is 470mm. The filter press is mounted onto a skid and includes the air operated diaphragm pump and all the necessary plumbing.

Met-Chem can run a customer’s 55 gallon drum of material at our facility. The customer is invited to come and watch the test to view the results, learn how a filter press operates, and to see our manufacturing facility.

Met-Chem can also rent out this filter press so it can be shipped and operated at a customer’s site. Since the unit is skidded it is easy to move and to put into place. All you need to do is connect to your source and you are ready to run the filter press.

Please contact the Met-Chem sales team to inquire about pricing, lead time, and current availability.

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc