Met-Chem manufactures new Filter Presses designed to fit your needs and budget. We offer a large variety of Filter Press sizes and options needed for your industrial application.

With over 60 years of experience, our team can help you select the right filter press, whether you need equipment for wastewater treatment, mining, plating, brewing, and any other tough industry. Let us help determine the correct filter press size and capacity for your specific need.

When selecting a Met-Chem Filter Press, you can choose among a wide array of options:

During the manufacturing process, you are always welcomed to visit our shop in Cleveland, Ohio to see your new filter press being built. We will be happy to provide periodic updates with e-mailed photos if desired.

Met-Chem can provide delivery and installation of your new Filter Press, both Domestically, and Internationally.

Manifold

Filter Plates

Manual or Hydraulic Pump

Steel Skeleton

Filter Presses have been the focus of Met-Chem Manufacturing for many years. Filter presses (also known as Plate and Frame) have many benefits. One, in particular, is that for such a large piece of machinery it has few parts to it.

The simplicity of the Filter Press means there is little maintenance work that is needed to be done to the press.

The filter press skeleton and filter press plates need zero repairs and as long as the press is operated properly. They will last a lifetime.

The different parts to a filter press include

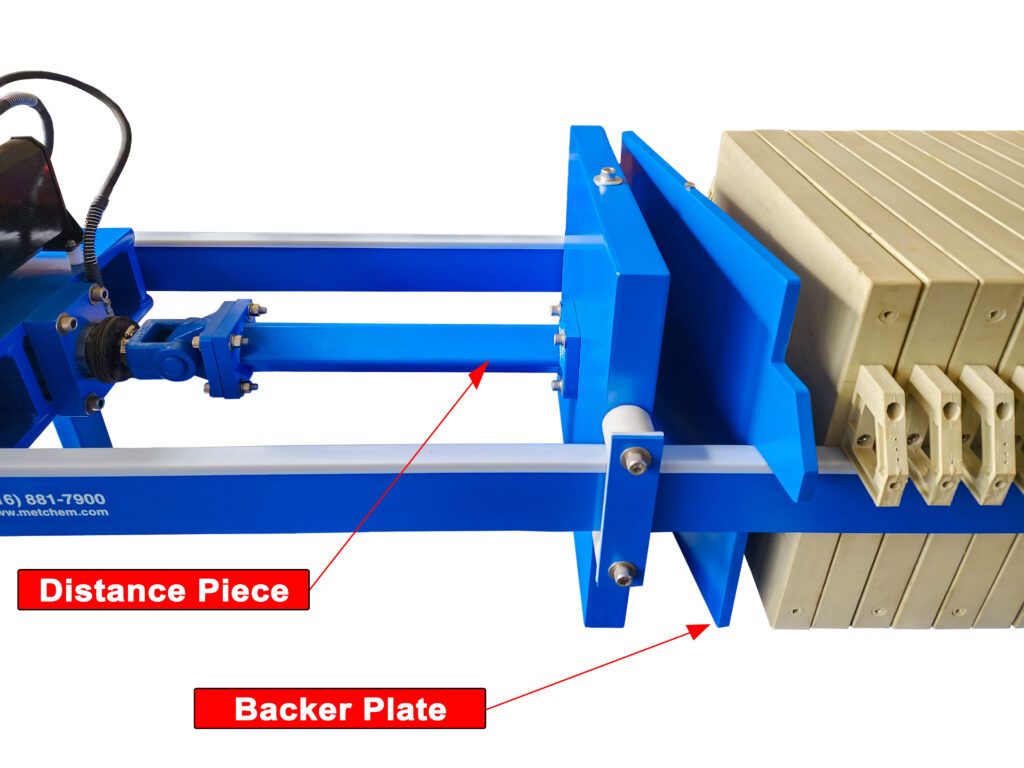

Filter Presses have been the focus of Met-Chem manufacturing for many years. We have built a solid reputation for building quality Filter Presses, Clarifiers, Sludge Dryers, Complete Waste Treatment Systems, Filter Press Cloths, and Filter Press Plates. Our filter presses have been used in a variety of industries from plating and metal finishing to chemical and food processing to name a few. Met-Chem Filter Presses feature heavy duty steel construction with polypro gasketed plates. These filter presses can be manufactured with manual or automatic closures, but always with a hydraulic cylinder for sure, high-pressure closing. Met-Chem’s filter presses can be expanded for larger future capacity by building it in a larger skeleton with a distance piece. Once you are ready to expand, you can remove the distance piece and add the extra plates.

More Filter Press Videos

The Met-Chem Backer Plate allows you to customize the size of the filter press. This is an fantastic feature when your sludge volume varies throughout the year. With a backer plate, you are able to move the tail plate up in the stack to make the filter area smaller. The metal backer plate will support the tail plate from damage.

A Backer Plate is an excellent option on a new filter press, and it can be installed on most existing filter presses.

The Met-Chem Distance Piece allows you to be able to expand the size of your filter press. By removing the distance piece, you are able to place additional filter plates in the press. This allows you to purchase a large filter press skeleton, without the need of purchasing all the plates at once. When you need to expand your filter press capacity, you can purchase the remaining plates at a later date. Thus, saving you money.

A Distance Piece is an excellent option on a new filter press, especially if you are expecting that you may need a larger filter press in the future.

The Met-Chem Semi-automatic Plate Shifter is our most popular requested add-on feature. The plate shifter makes operating your filter press easier, safer, and more efficient. Met-Chem offers various styles and levels of Automated Plate Shifters.

With large filter press plates, it would take two employees to move each plate and empty the filter press. The semi-automatic plate shifter allows one person to shift the plates. Thus, Saving You Money on Labor, and increasing productivity. Watch the video to see the plate shifter in action.

Met-Chem can add-on, rebuild and retrofit your existing filter press with a Semi-automatic Plate Shifter.

Met-Chem Bomb Bay Doors will catch dripping water that may come out of the plates during operation. These are typically used with Non-Gasketed Filter Press Plates since they are more prone to leak, as our gasketed plates will not leak. The excess water that leaks from the non-gasketed plates will be collected in a gutter system or perhaps a floor drain.

This add-on option can be installed with a new Met-Chem Filter Press or retrofitted for your existing filter press.

When the filter press is ready to be emptied, open the Bomb Bay Doors, and the sludge can be collected using a Met-Chem Sludge Dumpster.

Sludge Dumpsters are used directly under the filter press to catch the sludge that is released from the filter press during cleaning.

The sludge dumpster is on casters for easy mobility, and it is equipped with forklift slats for convenient use with a tow motor. The operator can move the dumpster to a roll-off container with the forklift and then pull the release pin for easy emptying.

The dumpster can then be snapped back to the upright position and put back under the filter press.

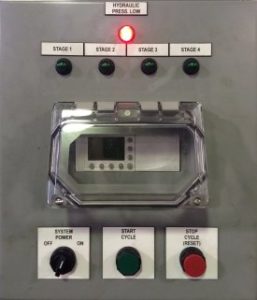

The Automatic Pump Control System automatically and gradually increases the feed pressure in four stages during the filling cycle. These stages are adjustable to suit your slurry and solids concentration. However, it is commonly set at increments of 25 psi. (25, 50, 75, 100). By monitoring the feed pump flow sensor, during the final pressure stage, the operator will be able to determine the cycle completion.

The Automatic Pump Control System also incorporates a low hydraulic pressure safety shut down the device. If there is not enough hydraulic clamping pressure present, the system will completely shut down, eliminating any possible leaking from between the filter plates.

The pump control system allows your filter press to run at its optimum efficiency creating dryer filter cakes, reducing disposal costs, reducing operator time, and increasing the life of your filter cloths and feed pumps.

This system can be incorporated with a new filter press from Met-Chem, a used unit, or even your own existing press.

Met-Chem can provide Longer Legs and a Disposal Chute on a new Filter Press, or retrofit your existing filter press. This is especially useful if you are releasing the sludge from the press into a sludge bag or a drum. The chute will direct the sludge directly into your container. If you plan to use a sludge disposal bag, we can add hooks to the chute so that the sludge bag can be hung from the frame of the press.

For some larger presses, we can build a catwalk along with the disposal chute in order to accommodate a roll-off container.

Air operated diaphragm pumps are used with filter presses to pump sludge from the bottom of the sludge holding tank into the filter press. These pumps are ideal because they can handle the slurry which is generally about the consistency of a milkshake.

The diaphragm pump usually starts out slowly and gradually ramps up. Once the pump starts to slow back down, (30-60 seconds between thrusts), it is usually an indicator that the filter press is full. At this point, the feed pump should be turned off and the valves on the filter press closed as the operator prepares to operate the air-blow-down process.

The diaphragm pump can be manually turned up or an Automatic Pump Control system may be added. This starts the pump at 25 psi, then moves up to 50, 75 and finally 100 psi which is standard operating pressure for the pump.

Met-Chem provides diaphragm pumps in the following sizes: 1”, 1.5”, 2” and 3”. The material of construction ranges from cast iron, aluminum, polypro or stainless steel.

With the purchase of a new Met-Chem filter press, Met-Chem can mount your air operated diaphragm pump to the legs of your filter press. This option also includes a flex hose that connects the outlet of the diaphragm pump to the center feed pipe, an air filter, a regulator, and an oiler. We can also provide a mounted diaphragm pump for your existing press.

Met-Chem is pleased to offer our spare parts kit which includes our 5 piece center feed pipe assembly, a head, tail, and 2 intermediate filter press cloths, and 100 foot of gasketing material. These are essential items for the operation of the filter press. A cracked pipe, ripped cloth, or torn gasket can happen anytime and having these items in your stock will ensure you will be back up and running in no time.

Met-Chem is pleased to offer our spare parts kit which includes our 5 piece center feed pipe assembly, a head, tail, and 2 intermediate filter press cloths, and 100 foot of gasketing material. These are essential items for the operation of the filter press. A cracked pipe, ripped cloth, or torn gasket can happen anytime and having these items in your stock will ensure you will be back up and running in no time.

Skid-Mounted Precoat Stations are custom built to work with any filter press (minor changes in the plumbing may be required). The basic precoating system includes a skid-mounted platform with a holding tank, mixer, controls, and a diaphragm pump. The precoat station can also be used as an Acid Wash System to clean filter cloths and maintain high levels of filtration.

The basic precoating operation involves mixing a slurry of filter aid, usually a combination of water and Diatomaceous Earth. The slurry is then pumped into the Filter Press and then recirculated into the holding tank. This process is run until the liquid appears to be clear or until the appropriate depth of precoat is achieved.

Skid-Mounted Precoat Stations can be customized and operated differently depending on the process of your specific application. Contact us for advice on the benefits of these portable skid-mounted systems.

Learn More about a Skid-Mounted Precoat System

When your daily wastewater needs to be collected and treated by a chemical process, a Met-Chem Batch Waste Treatment System can be built to accompany your filter press.

Learn More about a Batch Waste Treatment System

Batch Treatment System are Customized for your Application. Some Features and Options for your system may include:

A center feed pipe assembly on a filter press should be able to last many years the same way any other type of plumbing will. However, if the material of the center feed pipe assembly is not strong enough to handle the corrosiveness of the solution running through the press then the center feed pipe assembly can corrode.

A center feed pipe assembly on a filter press should be able to last many years the same way any other type of plumbing will. However, if the material of the center feed pipe assembly is not strong enough to handle the corrosiveness of the solution running through the press then the center feed pipe assembly can corrode.

For cases of corrosive material or high temperatures, Met-Chem is pleased to offer upgrades from our standard center feed pipe and manifold. We are able to upgrade to CPVC, Carbon Steel, 304 or 316SS Stainless Steel, and Titanium. Met-Chem can also provide additional manifold upgrades such as automatic valves

The center feed pipe is what connects the filter press to the product that needs to be filtered. The center feed pipe assembly consists of five different parts. The first part is the lock nut which fastens on the center feed pipe and connects to the outside of the press. The pipe, which is the second part, goes through the head of the filter and all the way through the head plate of the filter press. The third part of the center feed pipe assembly is a gasket which ensures the assembly is watertight. Next, is the clip nut seat which fastens the assembly to the head plate. This part of the assembly will always stay in place unless you are replacing the assembly or one of its parts. The final part, the cloth clip nut, will be removed often as it is screwed into the cloth clip nut seat after the head cloth is put on the head plate. The cloth clip nut needs to be tightened in order to keep the cloth in place. Met-Chem provides a tool to make this process easier. The Met-Chem Spanner Wrench is a specially designed tool that can be used to loosen and tighten the cloth clip nut when changing the head cloth on a filter press. This tool can be very helpful as the cloth clip, but it has a design that requires a unique tool to tighten and loosen it.

Sludge Dumpsters are used directly under the filter press to catch the sludge that is released from the filter press during cleaning. The dumpster is on casters for easy mobility. They are also equipped with forklift slats for convenient use with a tow motor. The operator can move the dumpster to a roll-off container with the forklift and then pull the release pin for easy emptying. The dumpster can then be snapped back to the upright position and put back under the filter press.

Sludge Dumpsters are used directly under the filter press to catch the sludge that is released from the filter press during cleaning. The dumpster is on casters for easy mobility. They are also equipped with forklift slats for convenient use with a tow motor. The operator can move the dumpster to a roll-off container with the forklift and then pull the release pin for easy emptying. The dumpster can then be snapped back to the upright position and put back under the filter press.

Met-Chem can provide longer legs and a disposal chute on your new filter press. This is especially useful if you are releasing the sludge from the press into a sludge bag or a drum. The chute will direct the sludge directly into your container. If you plan to use a sludge disposal bag, we can add hooks to the chute so that the sludge bag can be hung from the frame of the press.

For some larger presses, we can build a catwalk along with the disposal chute in order to accommodate a roll-off container.

Our standard filter presses can be operated manually. However, Met-Chem manufactures four types of filter press plate shifters to make operating your filter press easier, safer and more efficient. Manual filter presses require more time and attention than the same filter press with an automatic plate shifter.

For some larger presses, we can build a catwalk along with the disposal chute in order to accommodate a roll-off container.

If you produce varying size batches of wastewater and subsequently less sludge, or if the overall volume of waste that is generated at your facility has been reduced, you can still utilize your existing filter press. With the purchase of a backer plate, you can alter the holding capacity of your press to meet your individual batch needs.

A backer plate provides support to the tail plate so that it can be moved anywhere in the plate pack in order to isolate the chambers between the feed end and the tail plate. If you try to use the tail plate in a different position in the plate pack without the backer plate, you run the risk of damaging the chamber of the tail plate.

There are different kinds of backing plates. Some are made of plastic and look much like a standard plate; we prefer to use ~3/8” thick flat stock steel and cut an outline of a plate. This is clearly visible when placed in the stack so that all around know that the filter press is not at full capacity. This steel backing plate is then painted with the same two-part epoxy coating as the frame of the filter press.

If you produce varying size batches of wastewater and subsequently less sludge, or if the overall volume of waste that is generated at your facility has been reduced, you can still utilize your existing filter press. With the purchase of a backer plate, you can alter the holding capacity of your press to meet your individual batch needs.

A backer plate provides support to the tail plate so that it can be moved anywhere in the plate pack in order to isolate the chambers between the feed end and the tail plate. If you try to use the tail plate in a different position in the plate pack without the backer plate, you run the risk of damaging the chamber of the tail plate.

There are different kinds of backing plates. Some are made of plastic and look much like a standard plate; we prefer to use ~3/8” thick flat stock steel and cut an outline of a plate. This is clearly visible when placed in the stack so that all around know that the filter press is not at full capacity. This steel backing plate is then painted with the same two-part epoxy coating as the frame of the filter press. Automatic Pump System Control Panel gradually increases the pump pressure up to 100 PSI for standard units. This allows for even filling of the filter chambers.

Automatic Pump System Control Panel gradually increases the pump pressure up to 100 PSI for standard units. This allows for even filling of the filter chambers. The start-up and installation options are available with all Met-Chem waste treatment equipment. We can provide full support as you get your system up and running. We have installation technicians and technical representatives that we can send to your facility to make sure the system is running as it should based on the engineering and design.

Our services include but are not limited to:

The start-up and installation options are available with all Met-Chem waste treatment equipment. We can provide full support as you get your system up and running. We have installation technicians and technical representatives that we can send to your facility to make sure the system is running as it should based on the engineering and design.

Our services include but are not limited to:

Filling Stage: The Slurry enters and fills the chambers through a feed pump.

Filtration Stage: Once the chambers are filled with the slurry, the pressure from the feed pump will force the liquid filtrate out from the chambers. The Filter Plates and Filter Cloths will capture the solid particles creating sludge.

Air Blowdown Stage: The Air Blowdown Procedure allows the remaining free liquid in the filter press to be purged before the filter chambers are opened. Air is entered through a filtrate port, and the remaining liquid is forced out. This improves cake dryness.

Cake Discharge Stage: Each chamber is opened for cleaning. The sludge is removed and the filter cloths are cleaned if needed.

Met-Chem’s Filter Press Feasibility Test is our most popular and common test conducted in our lab. This test is performed to ensure that a filter press is able to filter solids properly with your specific application. The test will allow us to determine cloth sizing and if any filter aid will be required for your slurry. With less than a gallon of your typical wastewater, we can see if a filter press will provide the desired result. We will then send you the filtrate (liquid) as well as the solids that we are able to separate from your waste stream. The filter press test will also provide information to estimate the percentage of solids in order to properly size a filter press unit.

In the diagram below, Met-Chem was able to take a sample slurry and filter the liquid from the solids.

A Turnkey Solution for a Unique Filter Press Situation: We were contacted by an energy company regarding their water filtration issues. The problem was their large filter press was suspended 16 feet about a trailer, and it needed to be replaced. Read More about the Filter Press Solution >>

From PF Online: Filtration: A Simple Solution for a Big Problem: New Product From: Products Finishing, Edited by Hannah Coombs, Assistant Editor from Products Finishing ~ Posted on: 2/1/2017 ~ Cloth blinding can be a major issue. Precoating might be the answer.

Filter Press: Plate and Frame vs. Recessed Plate What is the difference between a plate and frame filter press and a recessed plate filter press?

Water Treatment Case Study: A Clean Lagoon is a Good Lagoon: Fiberboard Manufacturer’s existing system could not handle the volume of paper pulp being generated. They needed to clear out the sediment that was accumulating in their lagoon that was in violation of environmental regulations.

Membrane Filter Press Article: A membrane press can reduce cycle time by approximately, 50% on average and, in some cases, even as much as by 75% depending upon the application.

Filter Press Case Study: No time to Waste – Emergency Filter Press Repair and Replacement: The client contacted Met-Chem with an immediate need for repair. Aside from the safety concerns of a damaged press, a filter press cannot run with a broken skeleton. For this application, waste was continuously generated, which rendered this an emergency situation.

Filter Press Case Study: Turning water into Gold: To dewater the gold concentrate, Met-Chem installed a 1200MM filter press, and to eliminate the need for tailing ponds, Met-Chem designed a 1500MM filter press to dewater the tailings concentrate.

There are plenty of reasons why a filter press may not ever have a final destination. Probably the biggest reason for this is because a filter press is so versatile that it can easily adapt to many different jobs without much modification.

Some other reasons why some filter presses need to be mobile is because their jobs are always moving. If different tanks need to be filtered at different times a mobile filter press can be used. A job site also may move, and the mobile filter press needs to move with it. Finally, some job sites only need a filter press for a short period of time and the mobile press can also satisfy this need.

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc