Sludge Dryers manufactured by Met-Chem are designed for small, medium and large quantity sludge generators. These dryers can fit under the filter press for direct loading or can be located elsewhere in the plant. The sludge is dried by the heated liner of our unit while it is broken-up and circulated by our spiral blade system. The dryer liner uses indirect heat sources from steam, electric strips or gas fire. Our preheated airflow system draws the moisture off the top of the internal dryer and out through our wet scrubber system. After typically 4-6 hours of drying time (depending upon the type and wetness of the sludge) the dried material is removed by simply opening our discharge panel underneath our units for gravity discharge into a container. Another option is to include a conveyor auger to move the sludge to an elevated container. You have options depending upon your particular space requirements or restrictions.

Our use of and indirect heat provides an even heating surface and allows for tighter temperature control making it less likely to cause the sludge to burn or smolder. It also eliminates the danger associated with an open flame.

Typical payback on a Met-Chem Sludge Dryer varies from about 1-2 years depending upon the specific application and existing hauling costs. A sludge dryer can reduce hauling costs by 50-75%.

Build to Your Specifications

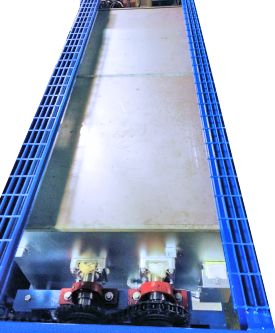

Sludge enters the top of the dryer from a Filter Press or Sludge Conveyor. After the Sludge Dryer is filled, the top lid will close.

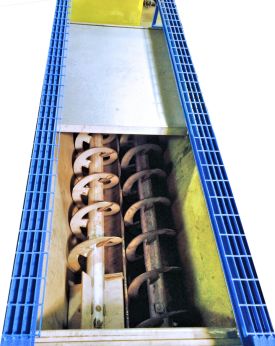

Heat is applied to dry the sludge, while the augers constantly toss and tumble the sludge for efficient drying. Fumes and small dust particles are processed by the wet scrubber.

The sludge is emptied out the bottom of the sludge dryer with the help of the augers. After the dried sludge has been emptied, the process is repeated.

A Met-Chem Wet Scrubber is specially designed for our sludge dryers. The air from the sludge dryer is combined with water and additional air. This will create a humid moist air chamber. When particles from the sludge dryer air collide with the water droplets, they will gravitate and fall to the bottom of the scrubber. The clean air is then exhausted. The wet scrubber will eliminate most of the particles and odors created from the drying process.

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc