We have yards filled with a wide variety of used equipment, some of them are in great condition, some are not… However any piece of equipment that has been refurbished by Met-Chem leaves our facility in excellent, “good-as-new” condition.

The equipment is disassembled stripped down to its basic parts. Major components are removed for reconditioning or replacement.

The reconditioning is not only for the outside of the clarifier. Both the inside and outside of the Clarifier are stripped and sandblasted to remove any loose paint, rust, or other materials.

The Clarifier is sandblasted, turned, and repositioned, so that everything is completely blasted and the surface is clean and ready for the next step.

This sandblasting process helps to expose any issues with the steel, joints, etc.

New metal is added to replace questionable or damaged metal. The legs, braces, brackets, and supports are all repaired or replaced.

As with the outside of the clarifier any internal parts are repaired, replaced, or fabricated.

Our team members have extensive knowledge and skills for building and fixing parts when needed.

The old flumes were beyond repair, Met-Chem fabricated new parts to factory original specifications.

Not only does this give Met-Chem the ability to proceed quickly, since we don’t have to wait for parts, but it also allows us to customize the project as needed by the client.

The exterior, safety blue, two part epoxy, consists of an epoxy resin which is cross-linked with a hardener. When catalyzed and applied, our epoxies produce a hard, chemical and solvent resistant finish for the clarifier.

The black, coal tar epoxy is applied to the inside of the clarifier. Coal tar epoxy is a heavy duty, high build protective coating commonly used industrially on barge hulls and underground tanks. This blend of epoxy resin and coal tar makes an excellent protective barrier coating for steel and iron.

The clarifier is repositioned and turned to ensure every crevice is completely covered and sealed.

The legs, braces, brackets, and supports are all painted as well. Special attention is given to joints and welds.

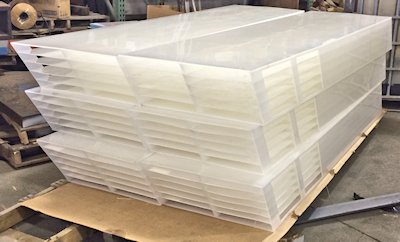

The Floc Tank Reconditioning Process is essentially the same process as the Clarifier Reconditioning Process.

Here are the before and after photos of a Floc Tank that was being reconditioned in tandem with the clarifier reconditioning process.

Flocculation Tank

The entire unit is dismantled, sandblasted, repaired, rebuilt or replaced as necessary. Then the unit is painted, sealed and reassembled. This particular floc tank was fully assembled with a clarifier that was being refurbished at the same time. Met-Chem performs the final factory acceptance test of quality assurance. This test includes the mixer gearbox and motor test, as well as water fill/leak test.

Flocculation Tank Motors

Flocculation Rake Mixer

Finally, the completed clarifier is reassembled, checked, and tested to ensure all the parts are working correctly, there are no areas to cause leaks, and the quality surpasses expectation.

Fully assembled, Met-Chem performs the final factory acceptance test of quality assurance. This test includes the mixer gearbox and motor test, as well as water fill/leak test.

You are welcome to inspect and sign-off on the unit before final payment. You can visit the clarifier in our shop or we can send a video of the unit in action. We are confident you will be impressed with the final product.

Once the unit passes our reconditioning tests and approved, it will ship with a 30-day warranty.

Either your team can reassemble the “good-as-new” clarifier, and any auxiliary equipment or our team is happy to offer Start-Up Assistance and Installation. We have installation technicians and technical representatives that we can send to your facility to make sure the system is running as it should be based on the engineering and design.

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc