Met-Chem has built a solid reputation for acquiring and Refurbishing Used Filter Presses and other filtration equipment in addition to our new equipment lines. We now also offer a large inventory of wastewater treatment and plating equipment. In an effort to keep up with demand, we are continually looking to expand our inventory. We are pleased to offer fair trade-ins and outright purchases of your surplus equipment.

We have yards filled with a wide variety of used equipment, some of them are in great condition, some are not… However any piece of equipment that has been refurbished by Met-Chem leaves our facility in excellent, “good-as-new” condition.

If you have any questions about our reconditioning, please contact us today.

The Filter Press is disassembled stripped down to its basic parts. Major components are removed for reconditioning or replacement. During the reconditioning process, you are always welcomed to visit our shop in Cleveland, Ohio to see your filter press being reconditioned. We will also be happy to provide Periodic Updates with E-mailed Photos if desired.

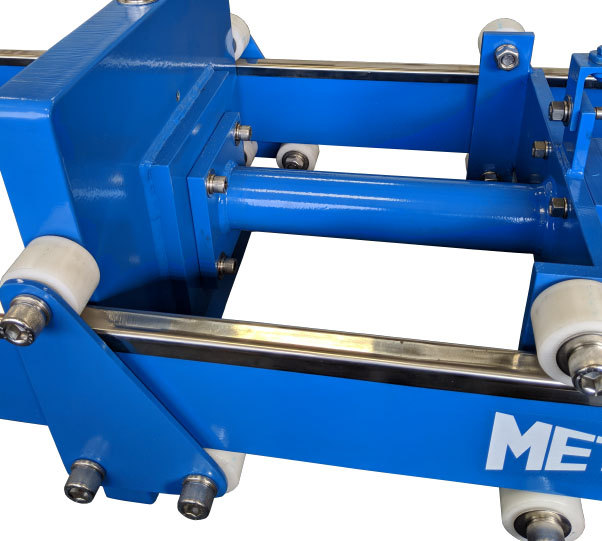

The filter press frame is Sandblasted to a white metal finish. This allows for an easy coating of the 2 part epoxy paint as well as a smooth finish

This Sandblasting process helps to expose any issues with the steel, legs, joints, etc. The entire frame is inspected, and the damaged areas are Replaced with New Metal when needed.

The Filter Press is painted with a safety blue, two part epoxy that consists of an epoxy resin which is cross-linked with a hardener. When catalyzed and applied, our epoxies produce a hard, Chemical and Solvent Resistant Finish to the filter press frame.

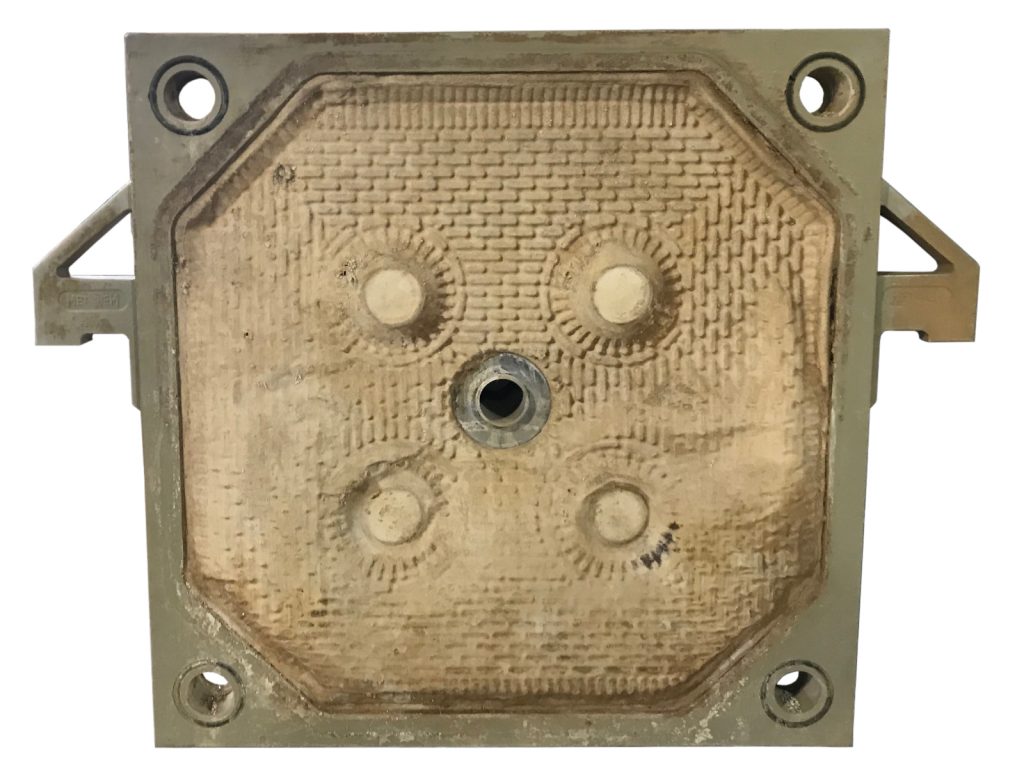

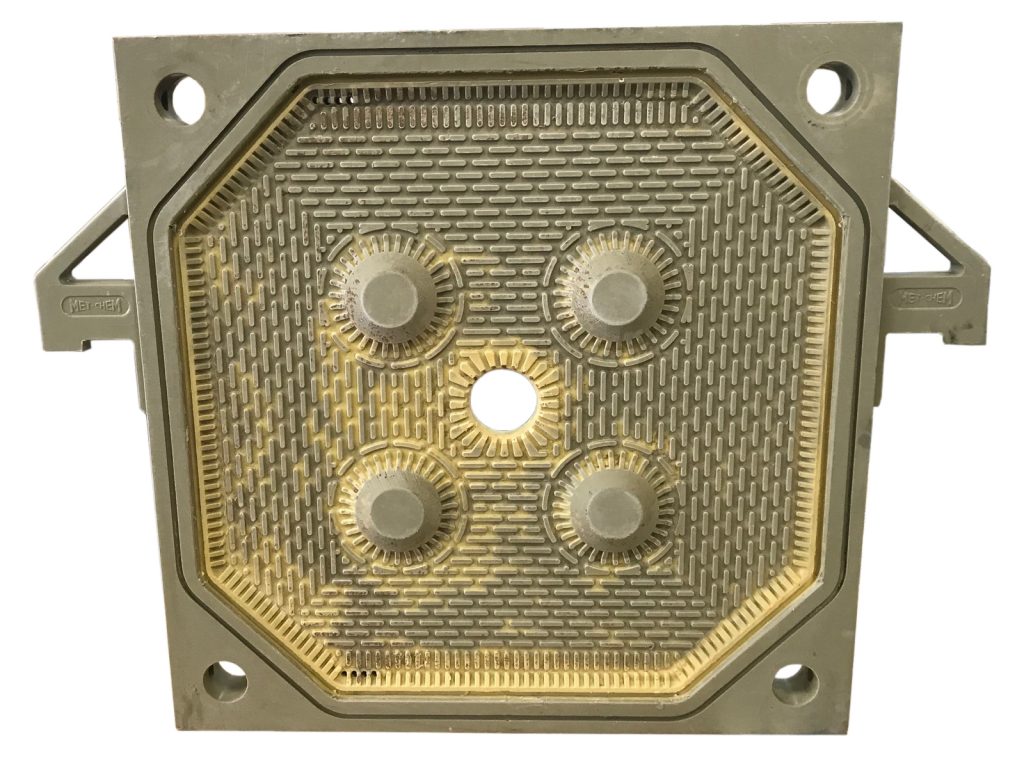

The Filter Press Plates are sprayed with a light acid solution and then Power Washed to remove all dirt and sludge. Some discoloration may occur, but this shouldn’t matter depending on your industrial application. You can receive an optional quote for new filter press plates. After the power washing, all the filter plates are inspected to see if there is any damage or cracks that may have been uncovered. All gasketing is inspected and replaced with new o-ring cord when needed.

After each Filter Plate is power washed and cleaned. New Filter Press Cloths are installed and in this particular case, new gasketing was installed.

The Filter Press Piping is inspected and replaced as needed.

Met-Chem can rebuild the filter press manifold to the specifications you need for your application. Below are the common sizes and materials used for the plumping.

The filter press Hydraulics are inspected and tested. Any faulty parts are Repaired, Rebuilt or Replaced as needed.

The Filter Press is reassembled and tested. You are welcomed to inspect and buy-off on the unit before final payment. Reconditioned items come with a Standard 30-day Warranty from date of the ship. Subject to review for your needs.

During the reconditioning process, you are always welcomed to visit us and inspect our progress, and we will be happy to provide periodic updates with e-mailed photos if desired.

If you have any questions about our reconditioning process, please contact us today.

After

After

Before

Before

After

After

Before

Before

After

After

Before

Before

After

After

Before

Before

After

After

Before

Before

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc