Gold mining facility

Initially there was a two-fold problem we were trying to solve. First, we needed to dewater the gold concentrate and eliminate the need to haul it away for separation. We also needed a system to eliminate the need for tailing ponds since they are not environmentally friendly. Tailings are a mixture of water and finely ground rock that is left over from mining operations once mineral concentrate is removed. They are typically stored in tailing ponds. Tailings usually contain about 10-20% of the economic minerals that could not be recovered from the ore. These ponds have historically provided an important water source for mine operations. The tailings water is usually pumped back to the mill to be reused in the milling process, thereby reducing the need for using new water. This being the case, it was imperative that we come up with a plan that would allow water reuse while eliminating the tailing ponds.

In our planning and analysis phase, we recognized the importance of having an automated system for this remotely located facility.

The Met-Chem engineering and design teams came up with a solution to address all of the client concerns.

The answers to each problem was a filter press. However, these filter presses needed to be as automated as possible.

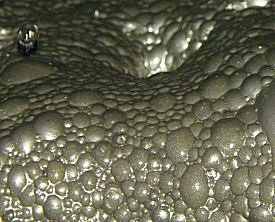

To dewater the gold concentrate, Met-Chem installed a 1200MM filter press to dewater the concentrate that is created from the gold separation process. This step is critical in the recovery of gold before it is sent to the smelter. Unlike a standard filter press operation involving settling metals, the gold concentrated is floated instead of settled. The gold concentrate forms a slurry which is skimmed and pumped into a holding tank before it is pumped to the filter press for final dewatering. The concentrated gold solids are put into bulk bags and shipped off to a smelter for final gold recovery.

To eliminate the need for tailing ponds, Met-Chem designed a 1500MM filter press to dewater the tailings concentrate. The water is pumped to holding tanks and reused in the gold separation process. The solids, which consist of non-ore-bearing rock, are recovered and are used to fill old mine shafts. The use of the Met-Chem tailing press provides the ability to return 100% of the tailings underground for a very low environmental impact.

Each Met-Chem Filter Press came equipped with Bombay doors for easy sludge dumping, automatic pump control systems to allow for even filling of the presses and pendant controlled automatic plate shifters. The plate shifters were critical due to the size of the plates. With the pendant style shifter, only one operator is needed to open and clean the press.

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc