Phosphating Wastewater Treatment Systems

Many industries use Phosphate Conversion Coating for surface pretreatment. This application is applied to steel that creates a thin layer of iron, zinc, or manganese phosphates to improve corrosion resistance and promotes better paint bonding. While many manufacturers use phosphate coating, it also creates a few challenges. Met-Chem specializes in keeping process tanks clean, treating phosphating wastewater through evaporation, a batch waste treatment system, or a continuous flow treatment system.

Process Tank Cleaning

Phosphating Process Tanks will build up with solids over time. When this happens the process tanks will need to be emptied and the solids will need to be shoveled out. This is costly as the entire tank needs to be drained and sent to wastewater treatment or hauled away. It is also a downtime that leads to a lot of labor.

Fortunately, the Met-Chem Filter Press easily fixes this problem. The filter press is connected to this process tank. It will constantly filter the contents of the tank and capture any solids that may begin to enter the tank. Due to the high temperature of these process tanks the filter press will use CPVC or a higher-grade material for its plumbing. The press will be sized to process the entire tank at least twice per day.

Learn More about a Filter Press to Keep your Process Tank Clean

Evaporation Systems

Evaporation is an excellent solution for companies that do not generate enough wastewater to justify a wastewater treatment system. It is a cost-effective solution to evaporate wastewater. Met-Chem offers thermal and atmospheric evaporation.

Wastewater Treatment Systems

Met-Chem offers a Batch Wastewater Treatment and a Continuous Flow Wastewater Treatment System. Each system is scaled and customized to treat your wastewater.

Met-Chem provides everything you need from start to finish including; wastewater testing, system design, drawings, equipment fabrication, turnkey installation, start-up, and training.

Ask Met-Chem about Phosphatizing Wastewater Treatment

Water Treatment Needs for

Metal Surfacing and Pretreatments

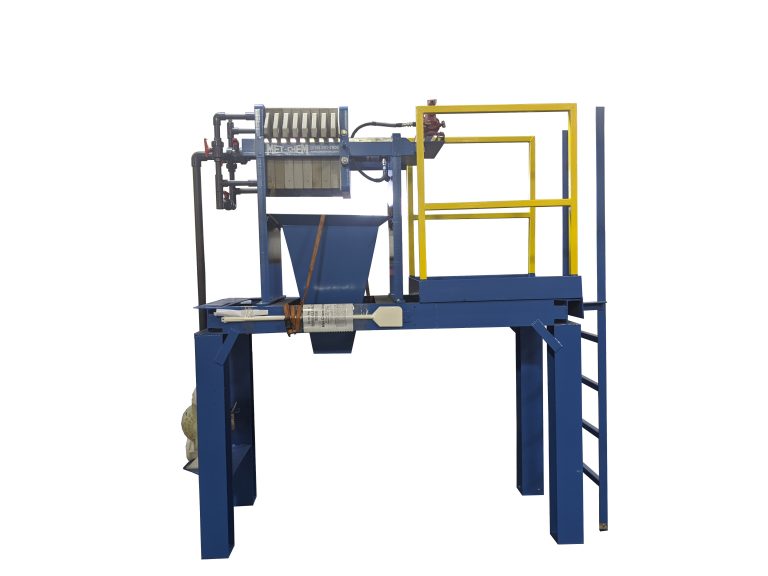

Met-Chem Filter Press

with Elevated Legs and Catwalk

Wastewater Treatment of

Phosphate Conversion Coating

- Zinc Phosphate Removal

- Iron Phosphate Removal

- Manganese Phosphate Removal

Filter Press for Phosphating Process Tank

Filter Press for Phosphating Process Tank

The incoming stream from the process tank will enter the Met-Chem Filter Press. The filter press will capture solids through pressure filtration. The sludge captured between the plates will be emptied after each batch operation. The remaining water is returned to be evaporated or treated.

Ask Met-Chem for

Additional Features and Customizations

Met-Chem Filter Presses

470mm Filter Press

1 to 5 Cu. Ft

- Automatic or Manual Hydraulic

- 5 to 29 Gasketed Filter Plates

630mm Filter Press

2 to 10 Cu. Ft

- Automatic or Manual Hydraulic

- 7 to 34 Gasketed Filter Plates

Sludge Dumpsters

Sludge Dumpsters are used directly under the filter press to catch the sludge that is released from the Filter Press during cleaning. The dumpster is on casters for easy mobility. They are also equipped with forklift tubes for convenient use with a tow motor. The operator can move the dumpster to a roll-off container with the forklift and then pull the release pin for easy emptying. The dumpster can then be snapped back to the upright position and put back under the filter press.

Ask Met-Chem for a Sluge Dumpster

Wastewater Evaporation Systems

Many companies are turning to evaporation systems to treat phosphating wastewater. An Evaporation System can reduce your need to haul away Expensive Wastewater, and therefore, the equipment would Pay for Itself in a manner of years. Met-Chem evaporators are scaled for your wastewater needs, and they are free of complicated machinery and chemistry. Their design provides consistent operation, minimal clean-out, high efficiency, and low maintenance.

Met-Chem offers two types of evaporation, Thermal and Atmospheric.

Ask Met-Chem about an Evaporation System

Batch Waste Treatment System

When your daily wastewater volume is not high enough to warrant a Met-Chem Continuous Flow Wastewater Treatment System then a Met-Chem Batch Wastewater Treatment System is the way to go. Our batch wastewater treatment systems range from 500 gallons per day up to 10,000 gallons per day.

Met-Chem can build a wastewater treatment system designed to fit your specific treatment needs. Learn more about a Met-Chem Batch Wastewater Treatment System

Ask Met-Chem about a

Batch Waste Treatment System

Continuous Flow Wastewater System

At Met-Chem our turnkey systems are custom designed, built and installed for your specific needs. We provide everything you need from start to finish including; wastewater testing, system design, drawings, equipment fabrication, turnkey installation, start-up, and training.

Ask Met-Chem about a Continuous Flow Wastewater

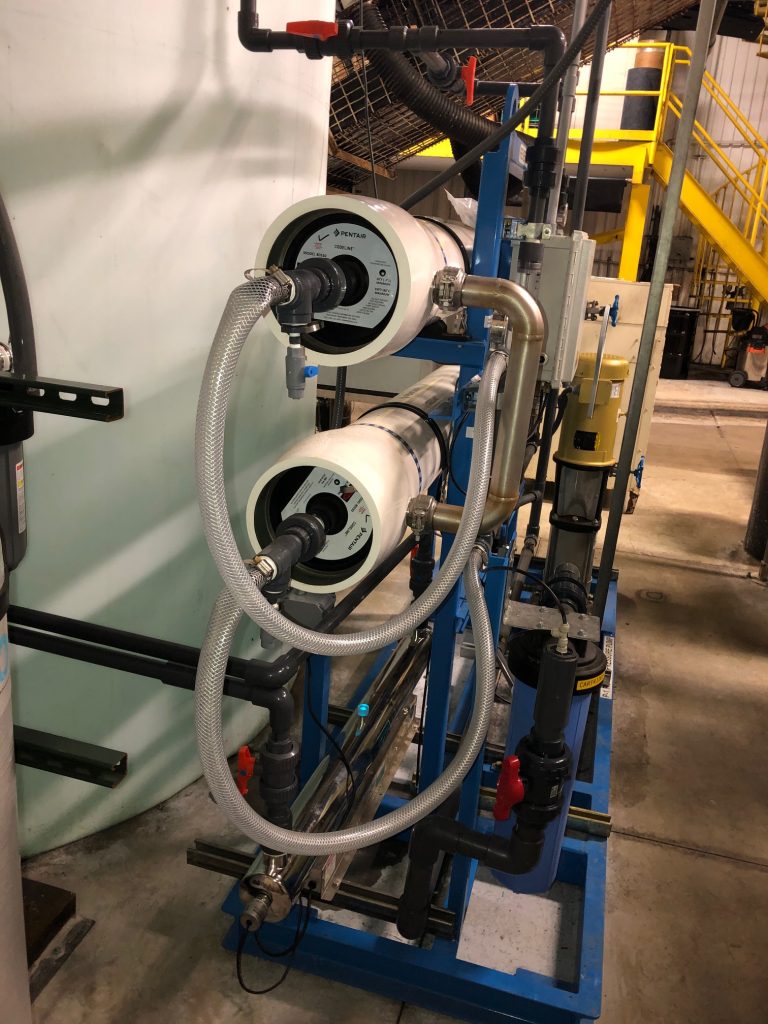

Rinse Water Purification System - RO / DI Water

Water Purification Schematic Flow Process

There are various water polishing schemes to purify water. Met-Chem will engineer the most cost-effective way to reach the purification level you are targeting.

In the diagram above, city tap water is run through the Activated Carbon Filter, and it will remove organic compounds found in water. This will prevent microbial fouling in the Reverse Osmosis System.

The water is then run through the Water Softener. This will protect your Reverse Osmosis System by removing scale-forming elements such as calcium that cannot be removed by the activated carbon filter.

The Reverse Osmosis System creates a very pure form of water. Reverse Osmosis is a water purification process that uses pressure and a semi-permeable membrane to remove dissolved solids. The RO water is stored in a holding tank.

If the RO water needs more purification, a Deionization System will reduce the conductivity of the RO water. The deionizer will remove trace minerals and charged ions from the RO Water. In the diagram, the RO water is recirculated continuously through the Deionization System where it can be used for rinses and make-up water.